Basic raw materials

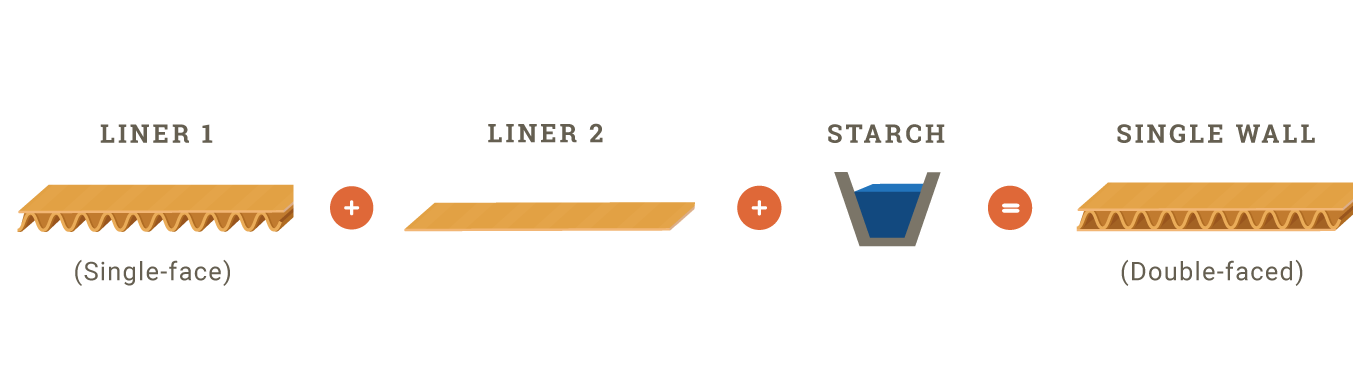

The papers used in the production of corrugated are specific grades called «Linerboard» and «Fluting Medium».

The adhesive which is applied to the tips of the flutes is starch usually manufactured from products of natural origin, the most common being maize (corn).

These three layers of paper are assembled in a way which gives the overall structure a better strength than that of each distinct layer.

This ingenious construction forms a series of connected arches which are well known for their ability to support strong weights. Arches have been used for structural engineering since ancient times and are commonly seen in the architecture of bridges and gothic cathedrals.

This structure gives corrugated board considerable rigidity and resistance. The air circulating in the flutes also serves as an insulator which provides excellent protection against temperature variations. It also provides a cushioning effect.

Renewable and natural resource

Corrugated is made from a renewable natural resource. The main raw material is paper, made up from cellulose fibres from wood or non-wood plants, which can be virgin or recycled, or a mixture of both.

Recycling in a closed loop, such as the paper cycle, can be seen as re-use of the basic materials.

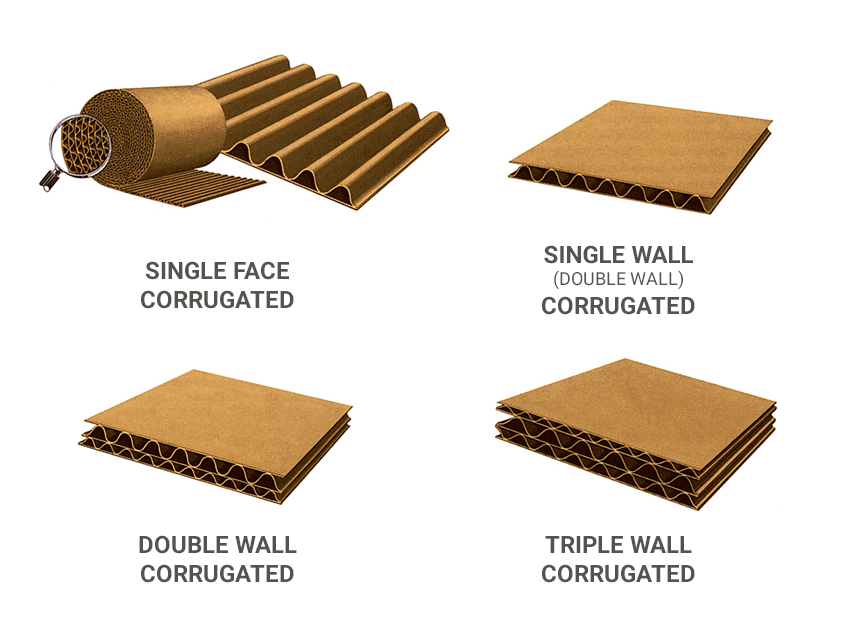

Construction Types

There are many construction types of corrugated, each with different paper grades and flute sizes and profiles which offer many a huge number of combinations designed to create packaging with different characteristics and performances.

Corrugated is a high-performance packaging material designed to pack, protect and promote products.